Chili powder, or chili powder, is a popular spice worldwide, widely used in cuisine and the food industry. To produce chili powder that not only retains its characteristic flavor and color but also meets strict international export standards, requires a strict production process and tight quality control from raw materials to final products. In this article, Viot Minh Trang will delve into the important steps and factors to create high-quality chili powder, and share how to preserve ground chili for a long time and the secrets to getting products ready to conquer international markets.

Types of chili used to make ground chili meet export standards

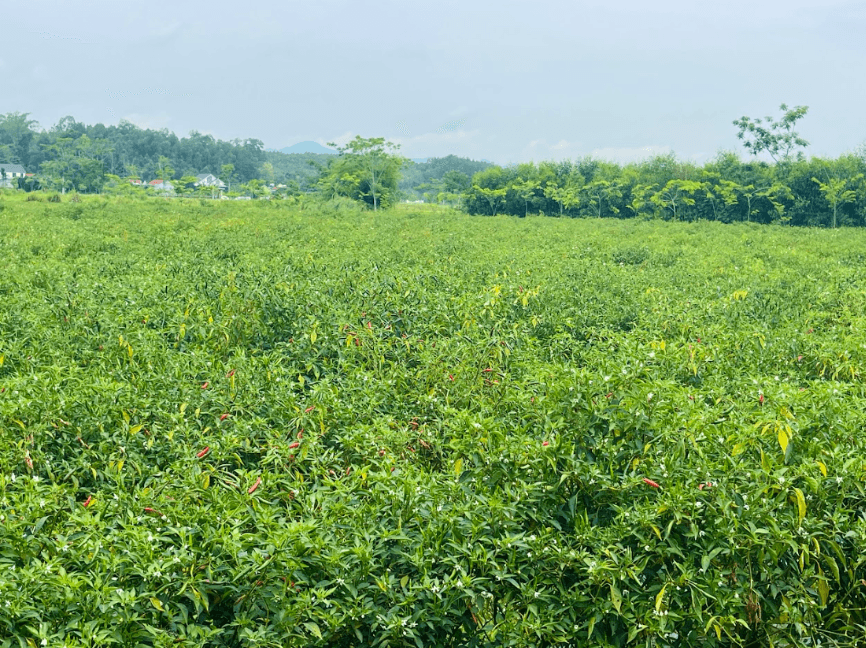

The quality of the finished ground chili depends largely on the selection and preparation of the original fresh chili ingredients. To meet export standards, the chili ingredients must meet the strictest criteria.

Criteria for choosing chili for making fresh ground chili

Fresh quality:Chili peppers must be fresh, not crushed, and have no signs of pests or rot. The color of the chili peppers must be bright, uniform, and reflect the true characteristics of the chili variety. This is a fundamental factor in how to make fresh chili high quality

Uniform ripeness:Choose chili peppers that are ripe and uniform, as this directly affects the color, flavor and spiciness of the finished chili powder. Chili peppers that are too young will be less spicy and pale in color, while chili peppers that are too old may be soft and spoil easily.

Shape and size:You should choose chili peppers with relatively uniform shape and size to facilitate the processing and drying process later.

Capsaicin content:Depending on the spiciness requirements of the import market, choose chili varieties with appropriate capsaicin (spicy substance) content.

Some popular chili varieties for export

Types of chili peppers commonly used in how to make chopped chili and ground chili for export includes:

- Chili pepper:Usually has moderate spiciness, beautiful red color, suitable for many dishes and markets.

- Chili pepper (chili pepper):Has a more spicy taste, suitable for products that require high spiciness.

- Red bell pepper (Capsicum annuum):Although less spicy, it is used to give color and mild flavor to some specialty chili powders.

The choice of a specific chilli variety will depend on the importer’s requirements for spiciness (Scoville Heat Units – SHU), colour and flavour.

Some popular chili varieties for export

Requirements on origin and cultivation

- To make ground chili meet export standards, the raw material source must be strictly controlled from the cultivation stage.

- VietGAP/GlobalGAP standards:Chilli peppers need to be grown according to good agricultural practice standards such as VietGAP (Vietnam Good Agricultural Practices) or GlobalGAP (Global Good Agricultural Practices). This ensures that the peppers are grown under hygienic conditions, without the use of pesticides or chemical fertilizers exceeding the permitted limits, and without other contaminants.

- Traceability:The entire process from planting, care, and harvesting must be recorded and traceable clearly and transparently.

See now:

Summary of the hottest peppers in vietnam

Detailed instructions on how to make ground chili for export

The process of processing ground chili for export must strictly comply with food hygiene and safety regulations and international quality standards.

Preparing fresh chili – First step in making fresh chili powder

- Receiving and classifying:Fresh chili peppers after harvest are transported to the factory, sorted to remove substandard fruits (crushed, diseased, too young or too old).

- Clean:Chili is thoroughly washed with clean water, can use high pressure spray washing system or specialized washing tank to completely remove dirt, sand and impurities.

- Drain:After washing, the chillies need to be completely drained. You can use a centrifuge or pre-dry/dry in a sterile environment to ensure the chillies are dry before entering the main drying stage. This step is extremely important to prevent the chillies from getting moldy during the drying process and to help old ground chili than

Preparing fresh chili – First step in making fresh chili powder

Drying Chili – Decides the quality of ground chili for long-term storage

- This is the most important step, directly affecting the quality and preservation ability of ground chili.

- Drying method:Modern drying methods such as convection drying, freeze drying (freeze drying) or infrared drying are commonly used. These methods help the chillies dry quickly, retaining their natural colour, flavour and optimum capsaicin content. Solar drying (greenhouse) can also be used under strict hygiene control.

- Temperature and humidity control:The drying process must be strictly controlled in terms of temperature and humidity to ensure that the chili is evenly dried from the inside out, reaching the required humidity (usually below 10%, or according to the specific standards of the importing country) without burning, discoloring or losing its smell. The drying temperature should not be too high to avoid reducing the quality of capsaicin and vitamins. This is especially important inHow to grind fresh chili to keep for a long time.

Grinding – Perfecting the chili grinding process

- Coarse and fine grinding:After drying, the dried chili peppers are put into an industrial grinder. The grinding process usually goes through several stages, from coarse grinding to fine grinding, to achieve the required chili powder particle size (e.g. fine powder, flakes, or broken particles).

- Grinding equipment:Use stainless steel grinding equipment that meets food hygiene standards, ensuring that no metal impurities are mixed into the product. The grinding process must be quick to avoid generating excessive heat that affects the quality of the chili powder.

Packaging and storage of ground chili

- Pack:After grinding, the chili powder is immediately packaged in specialized packaging (zip bags, aluminum bags, plastic or glass jars) that are moisture-proof, light-proof and airtight to maintain quality. The size and packaging materials must comply with the regulations of the import market.

- Preserve:The product must be stored in a cool, dry place, away from direct sunlight and high heat sources. Storage temperature and humidity must be controlled to prevent the growth of mold and bacteria.

Packaging and storage of ground chili

See now:

Discover the spicyness of vietnamese chili: Are Vietnamese chili the spiciest?

Quality control and inspection for exported ground chili

For exported ground chili to be accepted in international markets, the product must undergo strict quality control and inspection processes, complying with national and international standards.

Sensory criteria

Color:Chili powder must have a natural color, characteristic of the chili variety, not faded, burnt or have strange spots.

Taste:Must have the characteristic aroma of dried chili, no strange smell, musty smell, sour smell or chemical smell. The spiciness must be appropriate for the type of chili and product requirements.

Status:Chili powder must be dry, not lumpy, and have no visible impurities (such as chili stems, leaves, dirt or rocks).

Physical and chemical index

Humidity:This is an extremely important indicator, determining the ability to preserve and prevent mold. Humidity must be within the allowable limit (usually below 10% or according to import market standards).

Capsaicin content:Ensure spiciness meets published standards.

Pesticide Residue Limits (MRLs):This is one of the most important and difficult criteria for agricultural exports. Residues of agricultural chemicals must be below the permitted threshold according to the regulations of the importing country.

Heavy metals:The content of heavy metals such as Lead (Pb), Cadmium (Cd), Arsenic (As) must be below the safe limit.

Mycotoxins:Aflatoxin in particular needs to be closely monitored, as it is a dangerous carcinogen that can develop on peppers if not properly dried and stored.

Microbiological indicators

Check microbiological indicators to ensure food safety, including:

- Total aerobic bacteria

- Coliforms, E.coli

- Salmonella, Staphylococcus aureus

- Yeast and mold

All these indicators must be within the permissible limits according to national standards (TCVN) and international standards such as ISO, HACCP, FDA, EFSA.

Inspection process

Export batches of ground chili must undergo representative sampling and analysis at accredited laboratories, using internationally standardized testing methods. The analysis results must be issued with a valid certificate to demonstrate that the product meets the requirements.

See now:

Update the latest export chili price today

VIOT Minh Trang – Prestigious manufacturer and exporter of high quality ground chili

In the global agricultural supply chain, choosing a reputable partner with high production and quality control capacity is a key factor. VIOT Minh Trang is proud to be one of the leading manufacturers and exporters of ground chili In Vietnam, committed to bringing products that meet international standards.

About VIOT Minh Trang and experience

VIOT Minh Trang is a company with many years of experience in the agricultural sector, especially in the production and processing of chili. With the vision of becoming a reliable partner for demanding markets, Minh Trang constantly invests in technology, processes and human resources to ensure that each product is of the highest quality.

Chili powder production process at Minh Trang

VIOT Minh Trang applies a closed, modern and internationally standardized chili pepper production process. From the stage of receiving fresh chili peppers, which are strictly controlled according to GAP standards, to the stages of preliminary processing, drying with advanced technology (such as infrared drying or convection drying) and finally grinding and packaging in a sterile environment.

The entire process complies with GMP (Good Manufacturing Practices) and HACCP (Hazard Analysis and Critical Control Points) principles, ensuring that the product always retains its optimal color, flavor and food hygiene and safety.

Quality commitment and certification

VIOT Minh Trang is committed to providing ground chili with superior quality, fully meeting international standards for the export market. The company has achieved many important certifications such as ISO 22000 on food safety management system, HACCP, and other certifications.

This demonstrates strict compliance with global food safety regulations and the ability to provide reliable products.

VIOT Minh Trang – Prestigious manufacturer and exporter of high quality ground chili

Competitive advantage

- Stable source of raw materials:Minh Trang has a controlled chili raw material area, ensuring stable supply and consistent quality.

- Modern technology:Applying advanced drying and grinding technologies helps optimize product quality.

- Strict quality control:Internal lab system and cooperation with reputable testing units ensure products meet all strict standards.

- Export experience:A team of experienced experts in the field of agricultural exports, ensuring smooth procedures and logistics

Conclude

Producing ground chili peppers that meet export standards requires a strict process from raw materials to finished products, ensuring that they meet international standards for quality and food safety. Mastering how to make chili powder, How to preserve fresh ground chili, and especiallyHow to make fresh ground chili to keep for a long time will help ensure product quality and increase competitiveness in the international market.

With a modern production system, strict control and commitment to transparency, Viot Minh Trang is a reliable choice for domestic and foreign partners looking for a stable and sustainable source of high quality ground chili.

Tác giả Tưởng Mạnh Biên

Là chuyên gia giàu kinh nghiệm trong lĩnh vực xuất khẩu nông sản. Với nhiều năm làm việc, nghiên cứu và trực tiếp tham gia vào các hoạt động sản xuất, kinh doanh và xuất khẩu nông sản, tác giả chia sẻ những kiến thức chuyên môn sâu sắc cùng các bài học thực tiễn giá trị nhằm hỗ trợ doanh nghiệp.

- Địa chỉ: Số 27, Tổ 23, Lĩnh Nam, Hoàng Mai, Hà Nội

- Email: viotvietnam.vn@gmail.com

- SĐT: 0977 728 269